VR training for standardization of security procedures

- A2A

In the energy field, ensuring the safety of plants and people is a top priority. The challenges companies face are numerous and complex: from accident prevention to environmental protection. For this reason, the training of technicians is crucial to ensure the proper operation of plants and the safety of everyone. Effective and engaging training, therefore, plays a basic role in order to ensure that technicians are constantly updated on best practices and the latest safety regulations.

Introducing AnotheReality’s virtual reality training solution

AnotheReality, a leading immersive reality company, has developed an innovative virtual reality VR-based training solution for A2A. Through the use of VR viewers and 360-degree video, technicians can fully immerse themselves in a virtual environment in which they explore and interact with the energy plant. Such an immersive and interactive approach to training offers many advantages over traditional methods, including greater engagement and a better understanding of information.

The case of A2A: how virtual reality improved training on safety procedures

A2A Group, a major player in the Italian energy sector, decided to use AnotheReality’s virtual reality training solution to improve its technicians’ training on safety procedures. A2A’s business environment demands a high level of expertise and knowledge of safety regulations, and virtual reality proved to be a perfect tool to meet these needs.

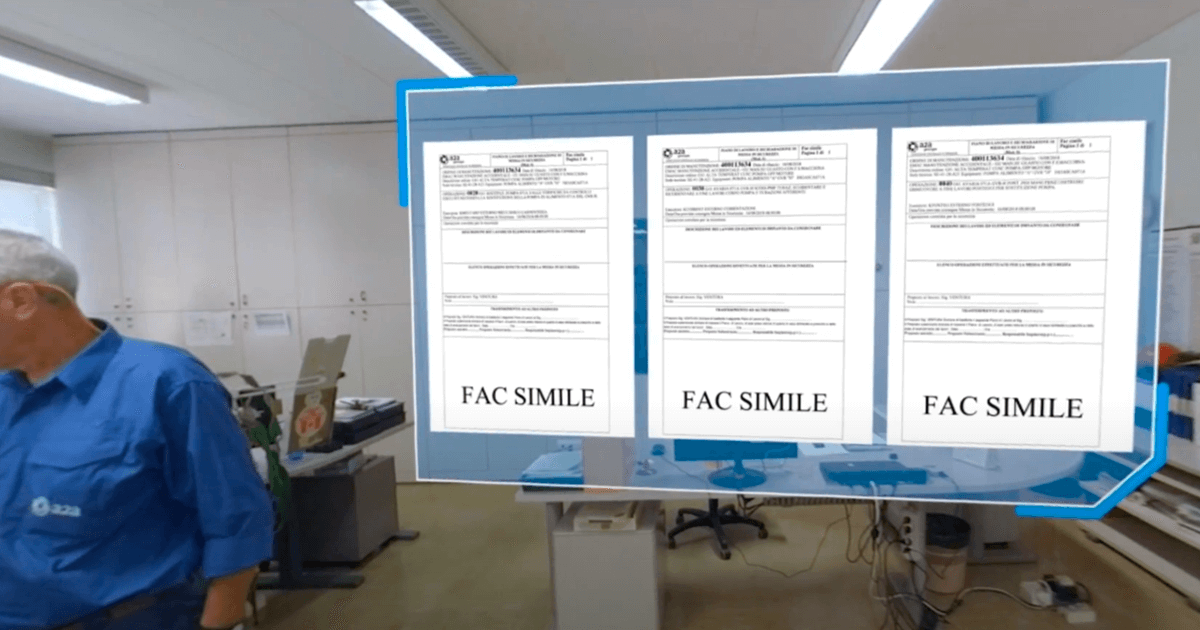

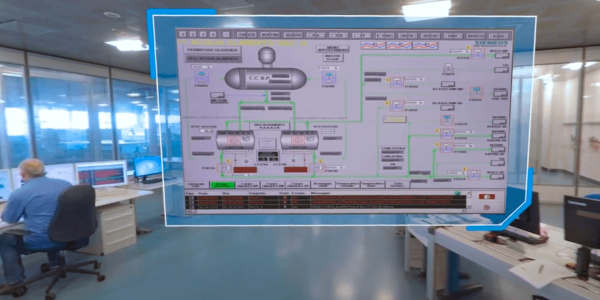

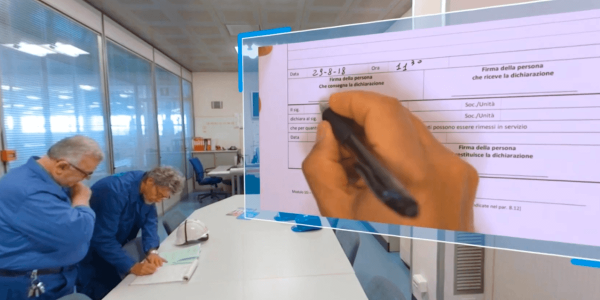

The VR experience proposed by AnotheReality consists of a 13-minute simulation, during which technicians immerse themselves in a virtual environment and follow a specific safety procedure. Due to the interactivity and realism of the experience, technicians become familiar with the procedures more effectively than traditional training methods.

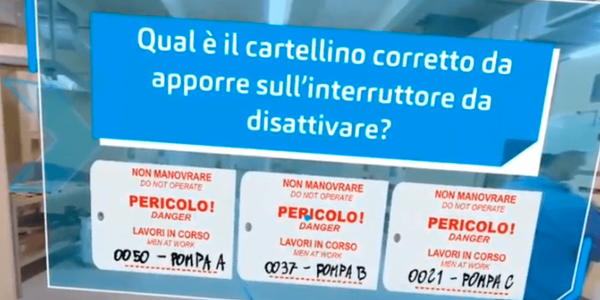

Interaction and skills testing: interactive quizzes and tests

During the VR experience, technicians not only have a subjective view of the plant but can interact with the 360-degree scenario by answering technical questions related to the safety procedure. At certain key moments, the user is asked to select the correct answer from those available. This participatory system allows them to check their understanding of the procedure and review their acquired knowledge. The quizzes and interactive tests play a key role in validating skills, but also in sustaining the motivation of technicians so that they constantly increase their skills.

Results and benefits of the virtual reality training solution for A2A

The results achieved by A2A with AnotheReality’s virtual reality training solution have been very positive. Feedback from technicians showed considerable improvements in training, both in terms of engagement and skill acquisition. In addition, virtual reality has reduced training time and increased process efficiency.

In addition to the immediate benefits, the VR system has significant potential for the future. Applications of virtual reality in the energy field can extend to various areas, from plant maintenance to emergency management. In addition, VR technology can also be used in other areas, such as medical training, occupational safety and education.

Conclusions

The success case of A2A and AnotheReality shows the great potential of virtual reality in the field of corporate training. VR makes it possible to overcome the limitations of traditional training methods, offering more immersive and effective experiences due to its immersive and interactive nature.

In an ever-changing industry such as the energy sector, the adoption of advanced technological solutions is of paramount importance to meet the challenges of the future and ensure the safety of plants and people. Virtual reality represents an opportunity for energy companies and all those who want to invest in innovative, immersive training that can adequately prepare professionals for the challenges of the future.

We selected 360° video technology to render the realism of the establishment, adding digital layers to make some steps related to the procedure clearer and engage the user.

The ways to test the user’s preparedness are based on simple gamification mechanics, such as multiple-choice questions.